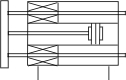

Product Name: TCL TCM Series Tri-rod Cyclinder Product Model: TCL12X90 TCL12X100 TCL12X125 TCL16X175 TCL12X150 Valve Type: Tri-rod Cyclinder, Cyclinder Brand: AirTAC Fluid: Air Acting Type: Double Acting

Specification:

| Bore size: | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | |

| Acting type: | Double Acting | ||||||||

|

Fluid: |

Air(to be filtered by 40μm filter element) | ||||||||

| Operating Pressure: |

0.1~1.0MPa(15~145psi) |

||||||||

| Proof pressure: | 1.5MPa(215psi) | ||||||||

| Temperature(℃): | -20~70 | ||||||||

| Speed rang (mm/s): | 30~500 | ||||||||

| Stroke tolerance: | (0~+1.0) | ||||||||

| Cushion Type: | Burmper | ||||||||

| Non-rotating Tolerance: | Linear Bearing: | ±0.08° | ±0.07° | ±0.06° | ±0.05° | ||||

| Brozen Bearing: | ±0.10° | ±0.09° | ±0.08° | ±0.06° | |||||

| Port Size: |

M5X0.8 |

PT1/8 | PT1/4 | ||||||

①Non-rotary accuracy of the cylinder fully retracted state, the cylinder fixed plate can be rotated angle;

②PT thread, NPT thread and G thread are available.

Stroke:

| Bore size(mm) | Standard Stroke(mm) | Max Stroke(mm) |

|

12 |

10 20 25 30 40 50 60 70 75 80 90 100 125 150 | 150 |

| 16 | 10 20 25 30 40 50 60 70 75 80 90 100 125 150 175 200 |

200 |

| 20/25 | 20 25 30 40 50 60 70 75 80 90 100 125 150 175 200 225 250 | 250 |

| 32/40/50/63 | 25 30 40 50 60 70 75 80 90 100 125 150 175 200 225 250 | 250 |

① Different from the standard stroke 1 ~ 5mm non-standard stroke cylinder, cylinder from the previous standard stroke restructuring, the same size and shape.

Such as the trip for the 86 non-standard stroke cylinder is a standard stroke of 90 standard cylinder restructuring, its dimensions and the same;

However, the non-standard stroke cylinder with a stroke of 84 differs from the standard stroke 90 of the previous stage by 6mm, and can only be ordered in non-standard form.

1. JIS standard is implemented.

2. Two guides of special bearing steel and linear bearing or bronze bearing guide are used to prevent rotating. They can bear high torque and radial load.

★Note: Steel ball linear bearing: It is suitable for elevation action of cylinder or the situation requiring high precision and high bearing ability, especially for the situation requiring low fraction action process.

Bronze sliding bearing: it is suitable for the action that has radial load resistance. Compared with normal cylinder of same use, the horizontal impact resistance is doubled and it has stronger torsion rigidity.

3. Drive unit and guide unit are in the same barrel that no additional accessories are needed with minimal space required. The air intake is optional and it is convenient to install.

4. The bottom, back side and fixing plate of main body respectively has two exact orientation orifices (See ΦPA orifice and the orifice in XX point), which can provide orientation installation with high precision for the special situation.

5. Options of switch mounting with provision 4 mounting slots.

6. Special design of main body provides multi-mount;

Installation & Usage:

1.When load changes in the work, the cylinder with abundant output capacity shall be ed.

2.Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion.

3.Necessary protection measure shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

4.Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

5.The medium used by cylinder shall be filtered to 40μm or below.

6.Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

7.The cylinder shall be carried out test run without load before application. Prior to run, buffer shall be turned to the minimum and gradually released to avoid the damage on cylinder caused by excessive impact.

8.The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

9.If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

| TCL12X25S | TCL20X150S | TCL32X150S | TCL50X150S | TCL80X60S | TCL100X40S |

| TCL12X50S | TCL20X200S | TCL32X200S | TCL50X200S | TCL80X70S | TCL100X50S |

| TCL12X75S | TCL20X250S | TCL32X250S | TCL50X250S | TCL80X75S | TCL100X60S |

| TCL12X100S | TCL25X25S | TCL40X25S | TCL63X25S | TCL80X80S | TCL100X70S |

| TCL12X150S | TCL25X50S | TCL40X50S | TCL63X50S | TCL80X90S | TCL100X75S |

| TCL16X25S | TCL25X75S | TCL40X75S | TCL63X75S | TCL80X100S | TCL100X80S |

| TCL16X50S | TCL25X100S | TCL40X100S | TCL63X100S | TCL80X125S | TCL100X90S |

| TCL16X75S | TCL25X150S | TCL40X150S | TCL63X150S | TCL80X150S | TCL100X100S |

| TCL16X100S | TCL25X200S | TCL40X200S | TCL63X200S | TCL80X175S | TCL100X125S |

| TCL16X150S | TCL25X250S | TCL40X250S | TCL63X250S | TCL80X200S | TCL100X150S |

| TCL20X25S | TCL32X25S | TCL50X25S | TCL80X25S | TCL80X225S | TCL100X175S |

| TCL20X50S | TCL32X50S | TCL50X50S | TCL80X30S | TCL80X250S | TCL100X200S |

| TCL20X75S | TCL32X75S | TCL50X75S | TCL80X40S | TCL100X25S | TCL100X225S |

| TCL20X100S | TCL32X100S | TCL50X100S | TCL80X50S | TCL100X30S | TCL100X250S |