Product Name: ACP Series Compact Cyclinder Product Model: ACP100X300 ACP100X325 ACP100X350 ACP100X275 ACP100X400 Valve Type: Compact Cyclinder, Pneumatic Brand: AirTAC Fluid: Air Acting Type: Double Acting、Single Acting Push、Single Acting Pull

Specification:

| Bore size: | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| Acting type: | Double Acting、Single Acting Push、Single Acting Pull | ||||||||||

|

Fluid: |

Air(to be filtered by 40μm filter element) | ||||||||||

| Operating Pressure: | Double Acting: | 0.1~1.0MPa(15~145psi)(1.0~10.0bar) | |||||||||

| Single Acting: | 0.2~1.0MPa(28~145psi)(2.0~10.0bar) | ||||||||||

| Proof pressure: | 1.5MPa(215psi) | ||||||||||

| Temperature(℃): | -20~80 | ||||||||||

| Speed rang (mm/s): | Double Acting: 30~500 Single Acting:50~500 | ||||||||||

| Stroke tolerance: | 0~150(0~+1.0) >150(0~+1.4) | ||||||||||

| Cushion Type: | Bumper | ||||||||||

| Port Size: | M5X0.8 | G1/8 | G1/4 | ||||||||

① PT thread, NPT thread and G thread are available.

Stroke:

| Bore size(mm) | Standard Stroke(mm) | Max Stroke(mm) | Allow Stroke(mm) | |

|

12 16 |

Double Acting: | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 110 |

200 |

200 |

| 120 125 150 160 175 200 | ||||

| Single Acting: | 5 10 | 10 | - | |

|

20 25 |

Double Acting: | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 110 | 200 | 200 |

| 120 125 150 160 175 200 | ||||

| Single Acting: | 5 10 15 20 25 | 25 | - | |

|

32 40 50 63 |

Double Acting: | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 110 |

300 |

300 |

| 120 125 150 160 175 200 225 250 275 300 | ||||

| Single Acting: | 5 10 15 20 25 | 25 | - | |

|

80 100 |

Double Acting: | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 110 |

400 |

400 |

| 120 125 150 160 175 200 225 250 275 300 325 350 375 400 | ||||

| Single Acting: | 5 10 15 20 25 | 25 | - | |

① other special itinerary please contact with the company;

②The 100mm range of non-standard travel range of more than a standard stroke restructuring, its dimensions for the previous standard stroke cylinder dimensions. Such as the stroke of 23 non-standard stroke cylinder is a standard stroke of 25 standard cylinder restructuring, its dimensions and the same.

1.In accordance with DIN standard, the mounting size is vogue.

2.The cylinder body connects with the threads of the front and back cover, forming high strength and convenient maintenance.

3.The internal diameter of the body is treated with rolling followed by the treatment of hard anodizing, forming an excellent abrasion resistance and durability.

4.The seal of piston adopts heterogeneous two-way seal structure. It has compact dimension and the function of oil reservation.

5.Compact structure can effectively save fifty percent installation space with ISO15552 standard cylinder.

6.There are magnetic switch slots around the cylinder body, which is convenient to install inducting switch.

7.Bumper is available and it can availably absorb excrescent energy.

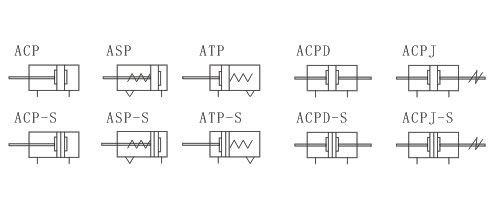

8.Installing accessories with various specifications are optional.

Installation & Usage:

1. When load changes in the work, the cylinder with abundant output capacity shall be ed.

2.Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion.

3.Necessary protection measure shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

4.Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

5.The medium used by cylinder shall be filtered to 40μm or below.

6.Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

7.The cylinder shall be carried out test run without load before application. Prior to run, buffer shall be turned to the minimum and gradually released to avoid the damage on cylinder caused by excessive impact.

8.The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

9. If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

| ACP12X5 | ACP20X10 | ACP25X45 | ACP40X15 | ACP50X30 | ACP63X45 |

| ACP12X10 | ACP20X15 | ACP25X50 | ACP40X20 | ACP50X35 | ACP63X50 |

| ACP12X15 | ACP20X20 | ACP32X10 | ACP40X25 | ACP50X40 | ACP80X10 |

| ACP12X20 | ACP20X25 | ACP32X15 | ACP40X30 | ACP50X45 | ACP80X15 |

| ACP12X25 | ACP20X30 | ACP32X20 | ACP40X35 | ACP50X50 | ACP80X20 |

| ACP12X30 | ACP25X10 | ACP32X25 | ACP40X40 | ACP63X10 | ACP80X25 |

| ACP16X5 | ACP25X15 | ACP32X30 | ACP40X45 | ACP63X15 | ACP80X30 |

| ACP16X10 | ACP25X20 | ACP32X35 | ACP40X50 | ACP63X20 | ACP100X10 |

| ACP16X15 | ACP25X25 | ACP32X40 | ACP50X10 | ACP63X25 | ACP100X15 |

| ACP16X20 | ACP25X30 | ACP32X45 | ACP50X15 | ACP63X30 | ACP100X20 |

| ACP16X25 | ACP25X35 | ACP32X50 | ACP50X20 | ACP63X35 | ACP100X25 |

| ACP16X30 | ACP25X40 | ACP40X10 | ACP50X25 | ACP63X40 | ACP100X30 |

| ACP20X5 |